High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

OLT-SD-5LCompliance:

CE CertifiedMinimum Order Quantity:

1Mixing method:

LCDCapacity:

10LVoltage:

380VDimension(L*W*H):

2500*1600* 2800mmWeight:

1500kgPackaging Details:

Standard export wooden boxDelivery Time:

6-8 day5L 10L 15L 20L 25L Stainless Steel Centrifugal Spray Dryer

|

Item

|

Unit

|

OLT-SD8000B |

OLT-SD-3L

|

OLT-SDS-3L

|

OLT-SD-5L |

OLT-SD-10L |

|

Max capacity

|

ml/h

|

1500-2000

|

3000

|

3000

|

5000

|

10000

|

|

Temperature range of inlet air

|

℃

|

40℃ ~ 300℃

|

30℃ ~ 300℃

|

30℃ ~ 300℃

|

140°C ~ 300°C Adjustable

|

50°C ~ 300°C

|

|

Temperature range of outlet air

|

℃

|

40℃ ~ 140℃

|

30℃ ~ 140℃

|

30℃ ~ 140℃

|

80°C ~ 90°C

|

30°C ~ 150°C

|

|

Temperature range of outlet air

|

℃

|

40℃ ~ 140℃

|

30℃ ~ 140℃

|

30℃ ~ 140℃

|

80°C ~ 90°C

|

30°C ~ 150°C

|

|

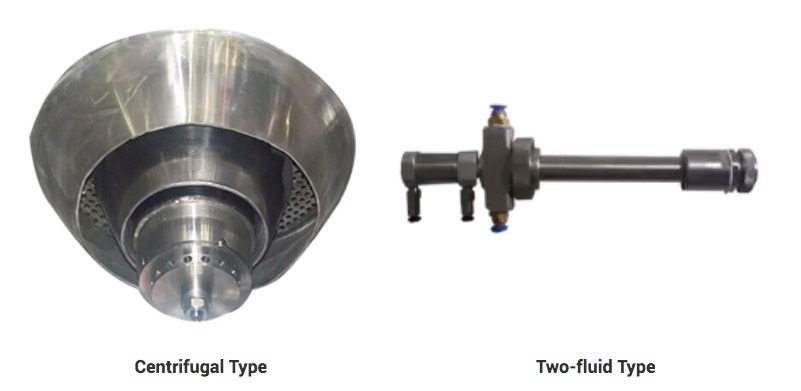

Spray system

|

/

|

Two-fluid nozzle

|

Two-fluid nozzle

|

Centrifugal nozzle

|

Centrifugal nozzle

|

Centrifugal nozzle

|

|

Precision of temp

|

℃

|

±1

|

||||

|

Dryer time

|

S

|

1.0 ~ 1.5

|

||||

|

Speed of squirt pump

|

ml/h

|

50 ~ 2000

|

3000

|

3000

|

5000

|

10000

|

|

Nozzle size

|

mm

|

0.5/0.7/0.75/1.0/1.5/2.0

|

\

|

\

|

\

|

|

|

Spray direction

|

/

|

Downwards co-current

|

||||

|

Heater Power

|

/

|

3KW 108V-240V

|

||||

|

Total power

|

/

|

10KW 380V

|

||||

|

Heat source

|

/

|

Electric

|

||||

|

Air compressor

|

/

|

Built-in oil-free air compressor

|

||||

|

Dried powder restoring rate

|

%

|

≥95

|

≥98

|

|||

|

Dimension

|

mm

|

940*850*

1500

|

1700*1100*

150

|

1700*1100*

150

|

1800*930*

2200

|

2500*1600*

2800

|

|

Maximum moisture evaporation

|

Kg/h

|

2

|

3

|

3

|

5

|

10

|

Working principle and Working Process:

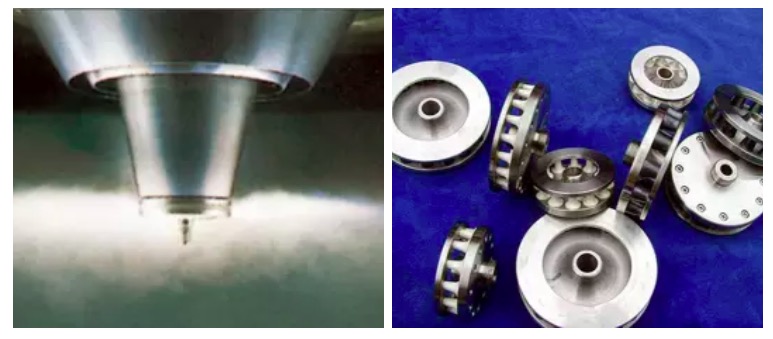

Air through filtering and heating, enter the hot air distributor which is at the top of spray dryer, hot air spiraling evenly into the drying chamber. Liquid through the high-speed centrifugal automizer which is at the top of drying chamber, (rotating) centrifugal spray into tiny fog droplet, then contact with the hot air flow, drying finish product in a very short time and whereabouts. Finished product output continuously between the drying tower bottom and cyclone separator, exhaust through dust catcher emptying by induced draft fan.

Pre-Sales Service:

Pre-Sales Service:

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529