High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

3-5 daysModel Number:

HR-KL-250Compliance:

CE CertifiedMinimum Order Quantity:

1Operation method:

PLC ControlMixing method:

Touch ScreenWarranty:

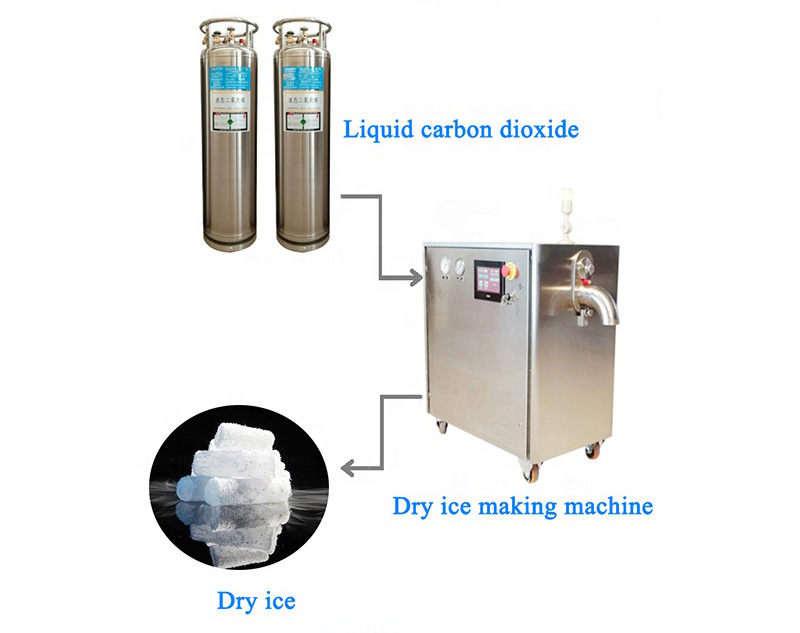

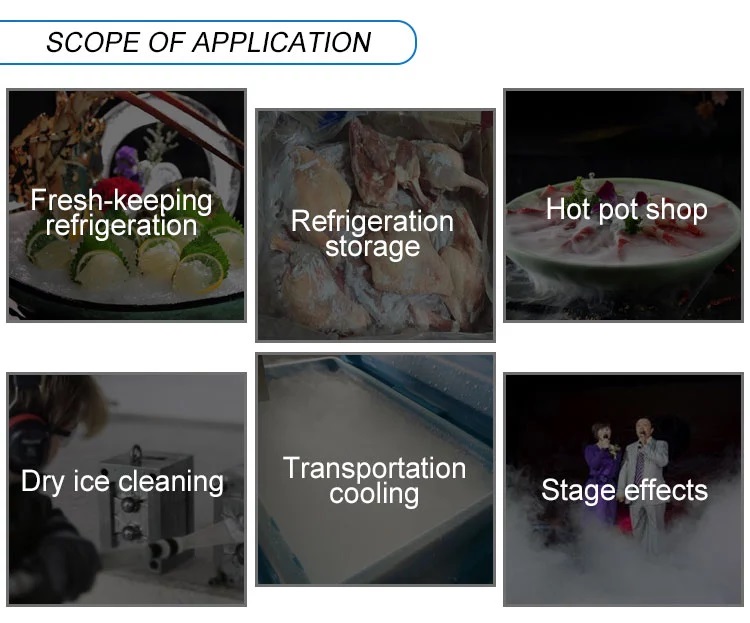

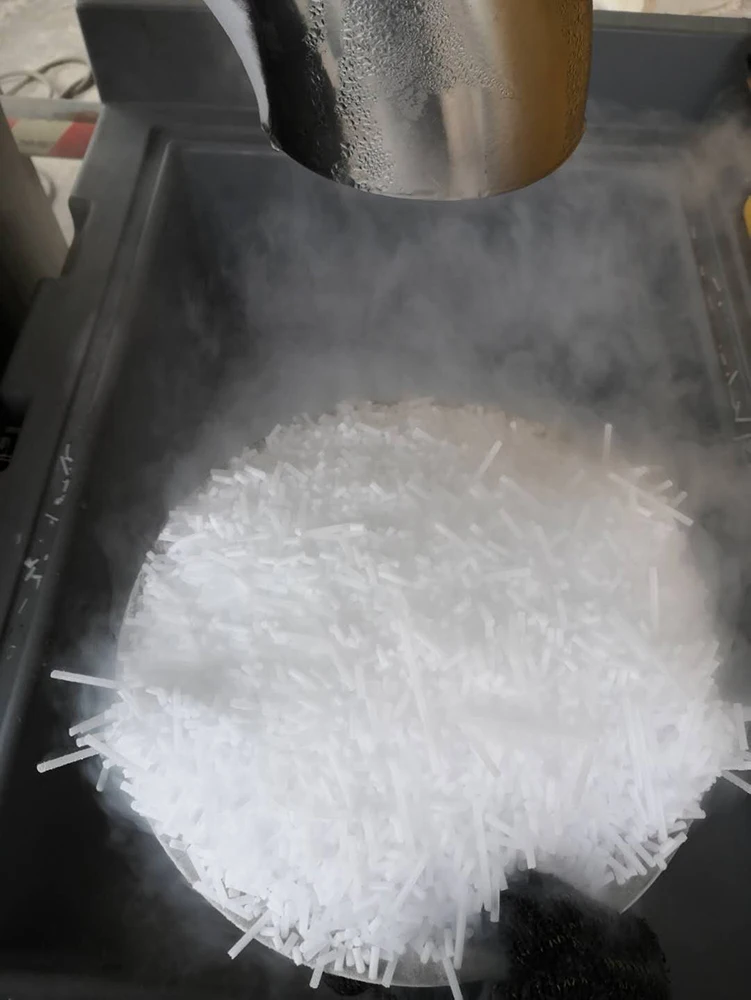

1 yearFull touch screen operation, PLC control system is adopted to further realize the full automation of the machine, improve the production efficiency, and greatly enhance the controllability and stability of the production process, making this series of dry ice pellets widely used in refrigeration storage, fresh-keeping cold chain, and transportation Cooling, dry ice cleaning and deburring industries. It can independently produce and customize various specifications of dry ice cube machines according to customer needs.

Parameter

| Model | HR-KL-50 | HR-KL-125 |

HR-KL-250 |

HR-KL-500 |

| Production capacity | 40-50kg/h | 125-140kg/h | 250kg/h | 300-500kg/h |

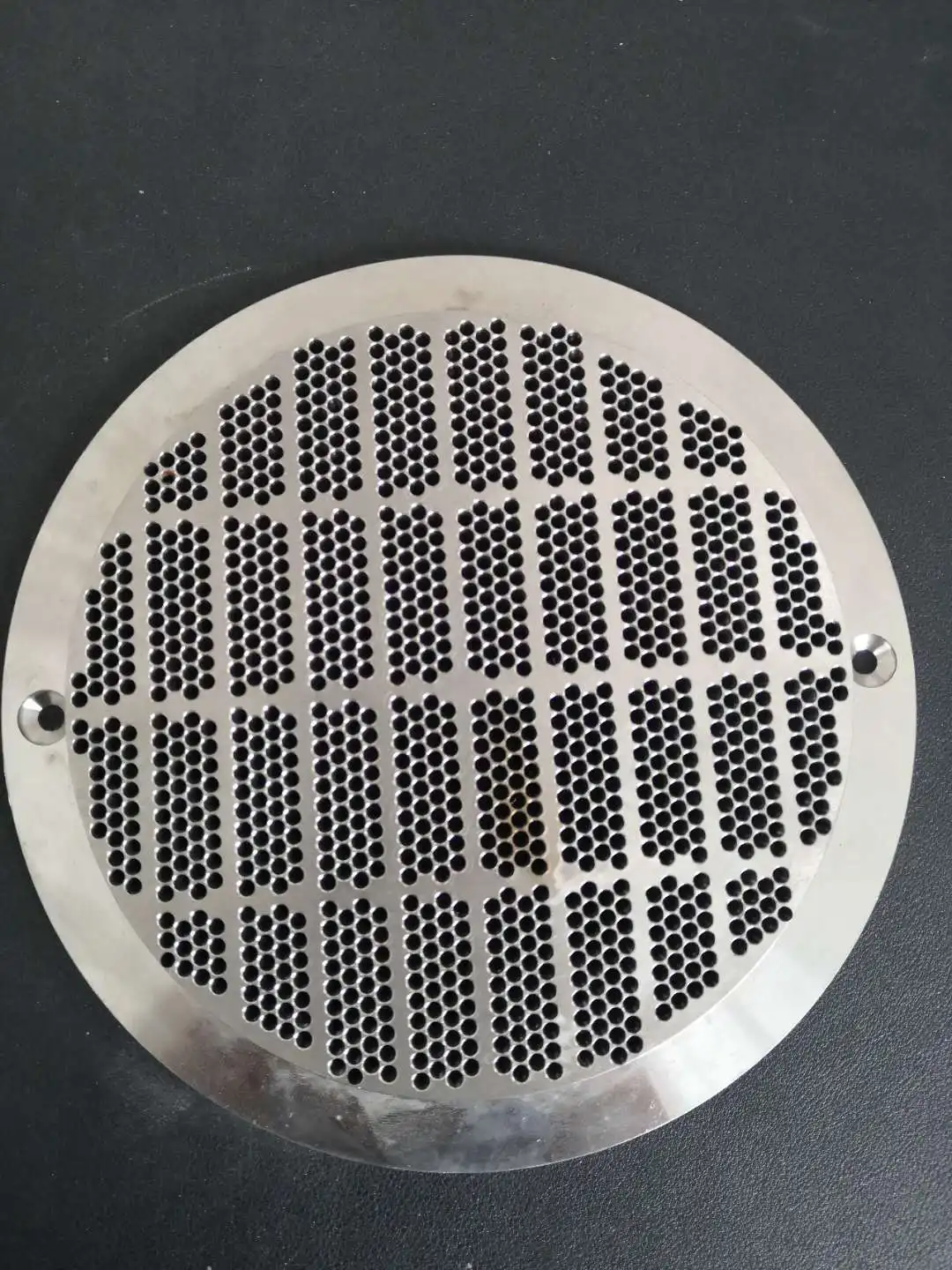

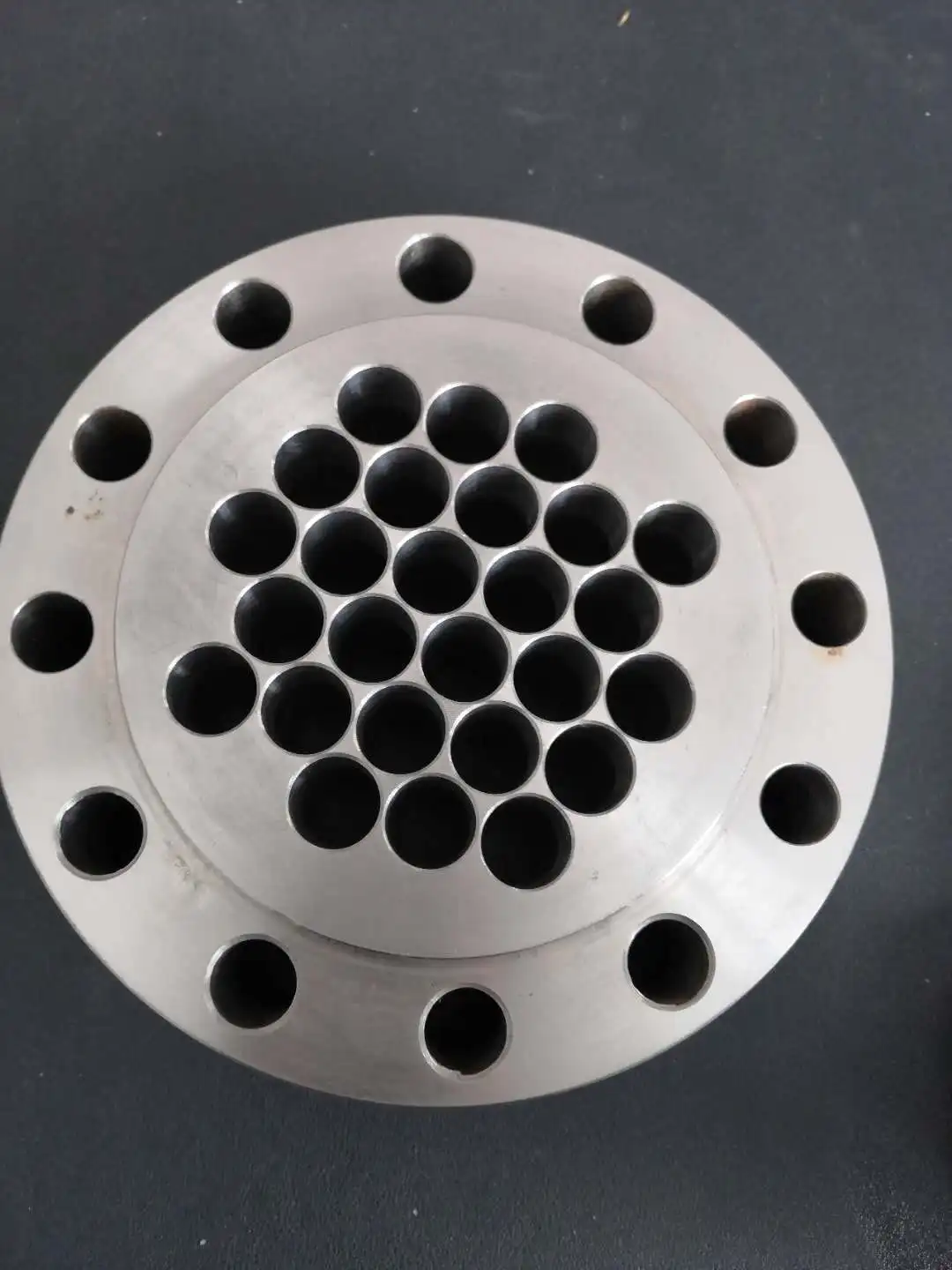

| Dry ice specification |

Φ3mm、Φ16mm |

Φ3mm、Φ16mm,19mm

|

Φ3mm、Φ16mm |

Φ3mm、Φ10mm、Φ16mm、 Φ19mm |

| The density of dry ice |

1550kg/m³ |

1550kg/m³ |

1550kg/m³ |

1550kg/m³ |

| Liquid and solid Co2 conversion ratio |

≥42% |

≥42% |

≥42% |

≥42% |

| The total power |

2.2kw |

5.5kg |

11kw |

18.5kw |

| Equipment weight |

200KG |

200KG |

1200KG |

1.8T |

| Overall dimensions |

100cm×50cm×100cm |

130cm×65cm×155cm

|

150cm×90cm×170cm |

160cm×135cm×175cm |

Features

1. The body is made of stainless steel, and the fully enclosed design makes the equipment more integrated, reduces the noise of the equipment when it is working, and prevents the danger caused by the accidental touch of the personnel during the work.

2. The core electrical parts are original.

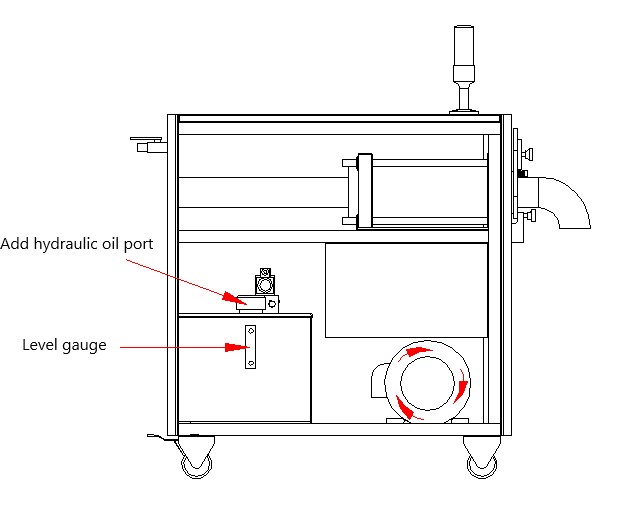

3. The hydraulic pump station and the pellet forming module are all built-in. On the one hand, it reduces the footprint of the equipment, and on the other hand, it also makes dry ice production avoid the impact of dust.

4. Touch LCD panel operation, you can set the number of hydraulic cylinder purge, working time, etc., reducing the error rate of manual operation.

5. Optional food-grade configuration of the hydraulic system (using stainless steel parts and edible food oil as the hydraulic transmission medium)

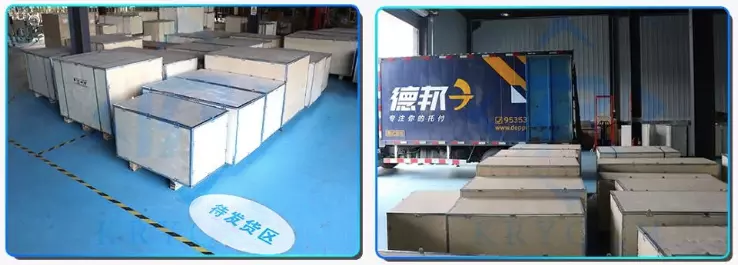

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529