High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

OLT450-210Minimum Order Quantity:

1Capacity:

210Warranty:

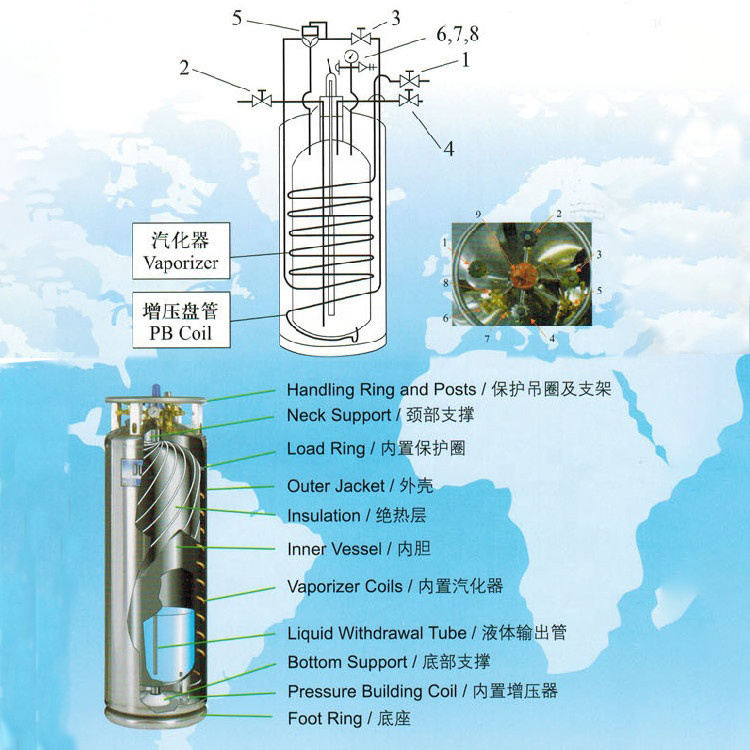

1 yearDewars are mainly used to store and transport liquid oxygen, liquid nitrogen, liquid argon and liquefied natural gas. The gas cylinder is designed as a double-layer (vacuum) structure. The inner box is used to store cryogenic liquids. The outer wall is covered with thermal insulation material. This product has the characteristics of safety and durability, large gas storage, no high-pressure explosion hazard, energy saving and environmental protection, and its own gas supply system.

Parameter

| Type | OLT450-175-1.4 | OLT450-175-2.0 | OLT450-175-2.3 | ||||||||||

| Nominal capacity(L) | 175 | 175 | 175 | ||||||||||

| Nominal pressure(Mpa) | 1.4 | 2 | 2.3 | ||||||||||

| Design temperature(℃) | -196 | -196 | -196 | ||||||||||

| Filling medium | LO2 | LN2 | LAr | LNG | LO2 | LN2 | LAr | LCO2 | LNG | LO2 | LN2 | LAr | LCO2 |

| Storage capacity/gas(Nm3) | 132 | 107 | 131 | 106 | 132 | 107 | 131 | 93 | 106 | 132 | 107 | 131 | 93 |

| Max. filling weight(kg) | 189 | 134 | 234 | 71 | 189 | 134 | 234 | 183 | 71 | 189 | 134 | 234 | 183 |

| Type | OLT450-195-1.4 | OLT450-195-2.0 | OLT450-195-2.3 | ||||||||||

| Nominal capacity(L) | 195 | 195 | 195 | ||||||||||

| Nominal pressure(Mpa) | 1.4 | 2 | 2.3 | ||||||||||

| Design temperature(℃) | -196 | -196 | -196 | ||||||||||

| Filling medium | LO2 | LN2 | LAr | LNG | LO2 | LN2 | LAr | LCO2 | LNG | LO2 | LN2 | LAr | LCO2 |

| Storage capacity/gas(Nm3) | 148 | 120 | 147 | 118 | 148 | 120 | 147 | 104 | 118 | 148 | 120 | 147 | 104 |

| Max. filling weight(kg) | 211 |

150 |

261 | 79 | 211 | 150 | 261 | 204 | 79 | 211 | 150 | 261 | 204 |

| Type | OLT450-210-1.4 | OLT600-360-2.0 | OLT450-210-2.3 | ||||||||||

| Nominal capacity(L) | 210 | 360 | 210 | ||||||||||

| Nominal pressure(Mpa) | 1.4 | 2 | 2.3 | ||||||||||

| Design temperature(℃) | -196 | -196 | -196 | ||||||||||

| Filling medium | LO2 | LN2 | LAr | LO2 | LN2 | LAr | LCO2 | LNG | LO2 | LN2 | LAr | LCO2 | |

| Storage capacity/gas(Nm3) | 158 | 127 | 157 | 273 | 221 | 270 | 191 | 218 | 158 | 127 | 157 | 111 | |

| Max. filling weight(kg) | 226 | 160 | 279 | 390 | 277 | 482 | 376 | 146 | 226 | 160 | 279 | 218 | |

Detail Image

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529