High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

ZS-401B-120Compliance:

CE CertifiedMinimum Order Quantity:

1Operation method:

ButtonWarranty:

1 yearThe material is placed in the casting mold and clamped between the electric-heating flat plates to apply pressure and temperature,make the material shaping,testing and serving as the basis for the ingredient of mass production.

Parameter

|

Model |

ZS-401A-120 |

ZS-401B-120 |

ZS-401C-120 |

|

Size of roll (mm) |

120X350 or customized |

||

|

Heating mode |

Electrical heating or oil heating |

||

|

Cooling mode |

Tap water cooling/oil cooling (optional) |

||

|

Roller speed |

Constant speed |

Single speed regulator |

Double frequency modulation |

|

Motor power (Kw) |

0.75X1®or customized |

0.75X1® or customized |

0.75X2or customized |

|

Volume (mm) |

1000X550X1200 |

1000X550X1200 |

1000X550X1200 |

|

Weight (kg) |

350 |

370 |

400 |

|

Power supply |

3ph, AC380V |

||

|

Special models can be designed according to customers requirements |

|||

Main Features

1) Equipped with a high performance hydraulic system with automatic pressure compensation function;

2) High precision and high wear-resistant guide posts to support strong load force and stable lifting;

3) Electric heating and PID temperature control to fast heat and precisely control the temperature;

4) Adjustable molding time;

5) Automatically increase and release the pressure when reaching the set time.

6) PLC Control system

Put the raw material into cast die and clamp the die between the electric heating plates of the machine,then apply heat and compress it in order to mold the raw materials to get the specimens for testing inlaboratory.

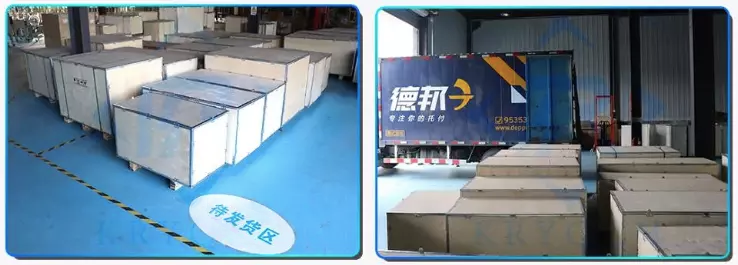

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529